Facilities

MGM FORGINGS BHARAT PRIVATE LIMITED

4 Plants in Mysore

▪ Heavy Hammers (80-800 kg)

▪ Drop Hammers (1-40 kg)

▪ Open die press lines (50-500 kg)

▪ Mechanical Presses (1-80 kg)

▪ Lasco extrusion press automatic line (15-100 kg)

▪ 24 In-house CNC Turning, Milling, VMC & HMC

▪ Strong vendor base located in Mysuru, Bengaluru, Coimbatore, Chennai & Pune

- Plant 1

- Plant 2

- Plant 3

- Plant 4

LASCO 1000T HYDRAULIC EXTRUSION PRESS WITH DRAW CARRIAGE TO PRODUCE HOLLOW FORGINGS

Weight Range : 15-100 kg (Diameter 200mm Max & Length 900mm Max)

HYDRAULIC PRESS PRE-FORGING/BLANKING

1000 Ton Press

Weight

Range : 50 - 100 Kgs

1500 Ton Lake Erie Press

Weight

Range : 50 - 500 Kgs

MECHANICAL FORGING PRESS LINES

6300 Ton, 4000 Ton, 2500 Ton (2 Nos), 1600 Ton, 400 Ton Screw Press

Weight Range: 1-80 kgs

HAMMER LINE – DOUBLE ACTING / COUNTER BLOW

32 Ton CBH Pneumatic, 25 Ton CBH Pneumatic, 16 Ton DA, 13 Ton CBH Hydraulic, 13 Ton CBH Pneumatic

Weight Range: 20 - 800 Kgs

Hammer Line - 16 Ton DA (40000 kg – m)

Weight Range -60 – 700 kgs

Hammer Line - 13 Ton CBH Pneumatic

Weight Range -20 – 60 kgs

HAMMER LINE – BELT DROP

1 Ton, 2 Ton, 3 Ton

Weight Range: 1-40 Kgs

Heat Treatment

Fully equipped heat treatment shop with the following facilities:

Normalizing, Hardening and Tempering, Isothermal Annealing, Solution Annealing with Quenching Media Polymer, Water and Salt Bath Quenching.

Small Batch Furnace

Capacity: 1.5 Ton/Batch

14 Nos

1. Heating Method: Oil, PNG & Electric Heating Coil.

2. Paperless Data Logger for Time and Temperature Recording.

3. Polymer & Water Quenching Facility with Capacity 14KL Each.

4. Submersible Type Agitation System for Better Agitation

5. Charging & Unloading Machine – Transfer Time: 45 Sec Max.

6. Temperature Uniformity Survey Conforms to API 6A & AMS 2750.

In-house Machining Facility

Equipped with high precision automatic machines capable of doing turning, drilling, threading, tapping & milling.

The machines are capable of holding components up to 500mm & weight ranging from 1kg to 80kg.

Machining Capability

- 5 VMC for Die Mould Manufacturing.

- Dedicated Die Welding Machine for Die Welding and Recut.

- 1 VMC with double column 6T capacity machine will be added shortly for bigger die machining.

- 11 CNC turning (STC-25-2, Hass-1, Doosan-1, Jyothi-2, Neri-1, CMTE-2, Pavan-1, Neri-1), 3 VMC (Doosan-1, AMS-1, Makino-1) for machining the components.

- Dedicated Setup for Chain Assembly.

- Horizontal Broaching Machine offers a 60-ton capacity and a 2-meter working length

- Further 7 VMC and 2 HMC has been added to strengthen in-house machining activity of forged components and to maintain timely delivery to Customers.

Testing Facility

- Chemical : Optical Emission Spectrometer

- Mechanical:

- Brinell, Rockwell, Portable Hardness Tester

- Universal Testing : Tensile, Bend & Compression

- Impact Testing

- Macro Etching Facility

- Zoom Stereo Microscope : X 25

- Metallurgical Microscope with Image Analyzer Software

- Sample Preparation Facility for Micro & Macro

- Hardenability : Muffle Furnace with Jominy End Quench Test Apparatus

- NDT Facility:

- Magnetic Particle Testing

- Ultrasonic Testing

- Liquid / Dye Penetrant Testing

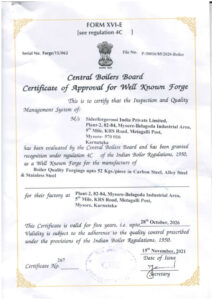

Quality Management System

| Download Certificate | Download Certificate | Download Certificate | Download Certificate | Download Certificate | Download Certificate | Download Certificate | ||

|---|---|---|---|---|---|---|---|---|

| Area of Certification | QMS | QMS | EMS | Health & Safety | PED | Aerospace | IBR | API |

| Description | ISO 9001:2015 | IATF 16949:2016 | ISO 14001:2015 | ISO 45001:2018 | PED 2014/68/EU | AS9100 D | Indian Boiler Regulations | API Q1 & API 20C |

| Certifying Body | TUV | TUV | MTIC | MTIC | TUV | TUV | Central Boilers Board | American Petroleum Institute |

| Initial Date of Certification | Jul'08 | Jul' 10** | Sep'12** | Sep'12** | Aug'18** | Jul'19 | Nov 13 | Sept 23 |

| Valid Up-to | September 2027 | September 2027 | October 2027 | October 2027 | August 2027 | July 2025 | October 2026 | September 2026 |

| By Quarter Q1-2025 - NABL accreditation for our in-house laboratory & NADCAP for Heat Treatment planned. | ||||||||

| **Earlier Version | ||||||||

HEAT TREATMENT

Fully equipped heat treatment shop with the following facilities:

Normalizing, Hardening and Tempering, Isothermal Annealing and Solution Annealing with Quenching Media Polymer Water.

Big Batch Furnace

Capacity: 10Ton/Batch

03 Nos

Aus-Tempering Furnace

Caopacity-0.5 Ton/Batch

01 no

1. Heating Method: Diesel, PNG & Electric Heating Coil.

2. Paperless Data Logger for Time and Temperature Recording.

3. Polymer 60 KL & Water Quenching Facility with Capacity 100KL.

4. Submersible Type Agitation System for Better Agitation

5. Charging & Unloading Machine – Transfer Time: 45 Sec Max.

6. Temperature Uniformity Survey Conforms to API 6A & AMS 2750.

HAMMER LINE – DOUBLE ACTING / COUNTER BLOW

32 Ton CBH Pneumatic

Weight Range -70 – 500 kgs

25 Ton CBH Pneumatic

Weight Range -70 – 350 kgs

13 Ton CBH Pneumatic

Weight Range -20 – 80 kgs

HEAT TREATMENT

Fully equipped heat treatment shop with the following facilities:

Normalizing, Hardening, and Tempering, Isothermal annealing, Solution annealing with quenching media Polymer and Water.

Batch Furnaces

Capacity- 1.5Ton/Batch

06 Nos

1. Heating Method: PNG & Electric Heating Coil.

2. Paperless Data Logger for Time and Temperature Recording.

3. Polymer & Water Quenching Facility with Capacity 14KL Each.

4. Submersible Type Agitation System for Better Agitation

5. Charging & Unloading Machine – Transfer Time: 45 Sec Max.

6. Temperature Uniformity Survey Conforms to API 6A & AMS 2750.